Who we are

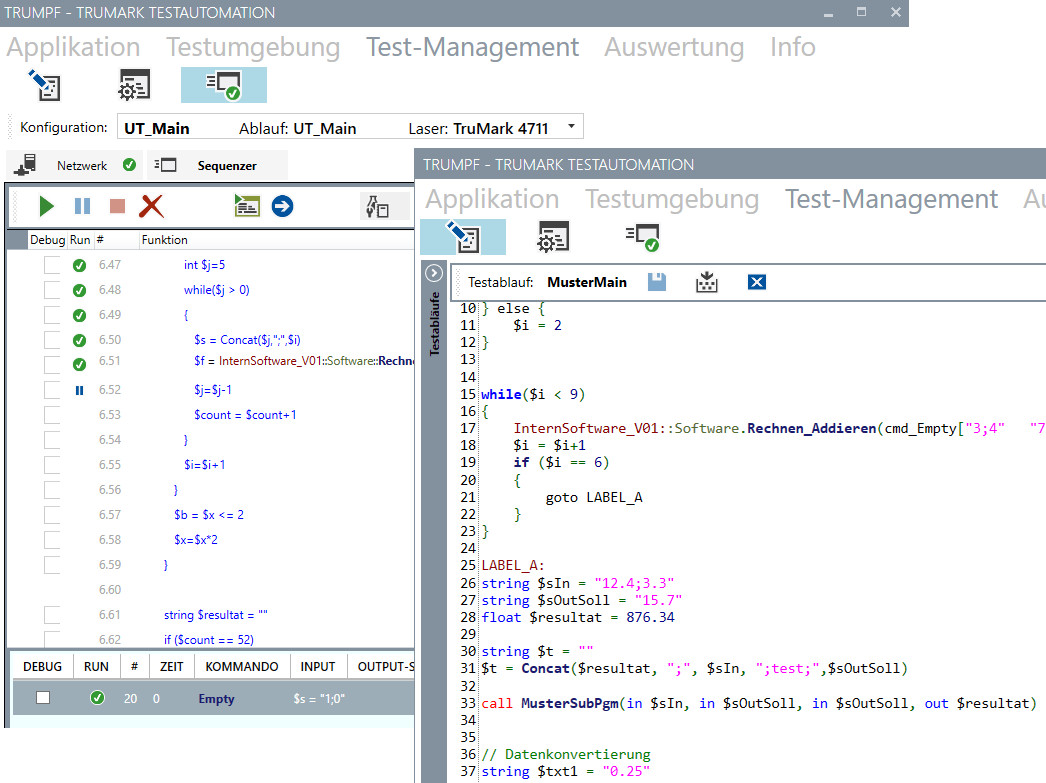

Erik Haller, founder of Intronic, has accumulated over 20 years of experience in developing tailored programming solutions to automation and business challenges, managing complex projects,

and cultivating deep understanding of diverse workflows to serve clients in a variety of industries.

In partnership with Switzerland-based Bühler-Mechatronik,

he spent over 10 years working collaboratively to design and build custom systems for the technology, process & analytics, medical, and research & development fields.

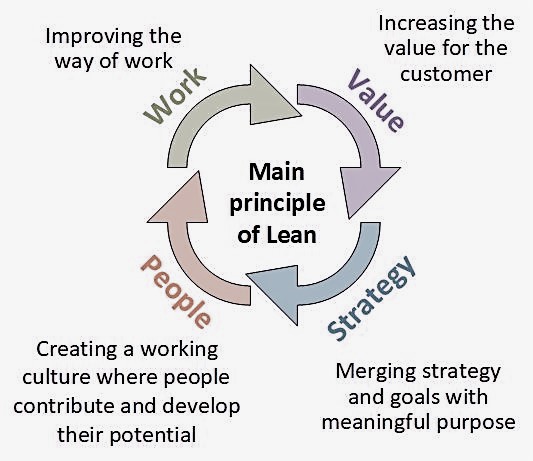

Intronic’s working relationships are grounded in skill and experience, and complemented by open communication, teamwork, and transparency.

We are goal-oriented and maximize return on investment within agreed-upon timelines.

Intronic was established in Canada in 2020.